India is facing an urgent need to develop concentrated tooling hubs to truly scale advanced manufacturing in the aerospace and space domains, according to S Somanath, former Chairman of the Indian Space Research Organisation (ISRO). He emphasized that India must create focused manufacturing ecosystems, similar to those in China, to achieve significant progress.

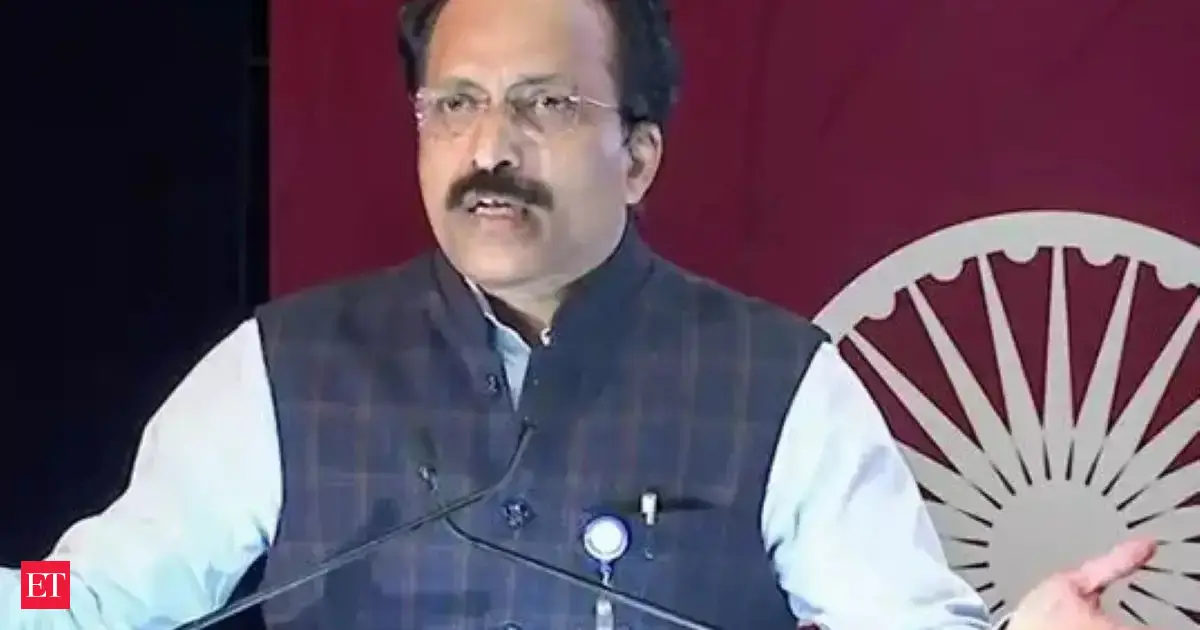

Speaking at the Accel Advanced Manufacturing Summit in Bengaluru, Somanath highlighted the absence of a comprehensive aerospace manufacturing framework in India. He suggested that distributed hubs across the country are not suitable for sectors like aerospace, advocating instead for concentrated hubs where all players are aggregated, along with institutions that add value to research and innovation.

Somanath also pointed out that specialized skills, such as tooling, are often overlooked in the domain. He stressed the need for individuals with extensive knowledge in tooling processes, metallurgy, materials manufacturing, machine tools, process engineering, and automation to build frontier tech capabilities in the coming decade.

The lack of sufficient supply is currently a bottleneck for Indian rockets despite strong global demand. Somanath emphasized that manufacturing is the crux of the problem, and the ability to manufacture and launch quickly is essential. He advised startups looking to build in the space sector that mass manufacturing in satellites and small launch vehicles will be necessary to capture the global market.

Echoing Somanath's sentiments, space startups and deep-tech investors noted that space as a defense technology has emerged later in India, requiring the nation to catch up in certain areas. Srinath Ravichandran, CEO of Agnikul Cosmos, suggested that the solution is not to mimic the SpaceX model but to build from scratch.

The establishment of dedicated manufacturing hubs is crucial, along with addressing supply chain challenges that hinder India's rocket production capabilities. Several states, including Karnataka, Maharashtra, Tamil Nadu, and Telangana, have the potential to become hubs for India's military aerospace ecosystem, collectively contributing nearly 70% of the work centers for the LCA Tejas aircraft ecosystem.

To enhance manufacturing capabilities, emerging technologies in tooling are essential. CNC machining of lightweight metals is particularly beneficial for aerospace applications, providing the precision needed to reduce aircraft weight while maintaining structural integrity. Automation and robotics are also increasing efficiency in tooling processes. Additive Manufacturing (AM), also known as 3D printing, has transformed the aerospace and defense sectors by enabling rapid prototyping and the production of complex, lightweight components. Digital twin technology is another tool that optimizes tooling performance by simulating tool performance in a digital environment and assessing the quality of parts.

Several companies are already contributing to India's aerospace manufacturing sector. Bharat Forge Ltd has signed a contract with Pratt & Whitney Canada to establish a new ring mill for aerospace applications, expected to be operational by 2026. This facility will produce high-performance aerospace products, supporting India's vision of becoming a global aerospace manufacturing hub. Jeh Aerospace has also secured $11 million to scale the commercial aircraft supply chain in India, building world-class precision manufacturing powered by software-defined manufacturing. The company has scaled to over 100 engineers and technicians, delivered over 100,000 flight-critical components and tools, and secured $100 million in contracts in 18 months.

India's satellite manufacturing sector is also experiencing growth, supported by government policies, technological innovations, and increasing involvement of public and private players. The liberalization of FDI in 2024 for satellite manufacturing and operation has further opened doors for foreign partnerships. India's competitive edge in cost-effective satellite production and ongoing technological advancements are solidifying its position as a global space leader, with the space economy projected to reach approximately USD 44 billion by 2033.