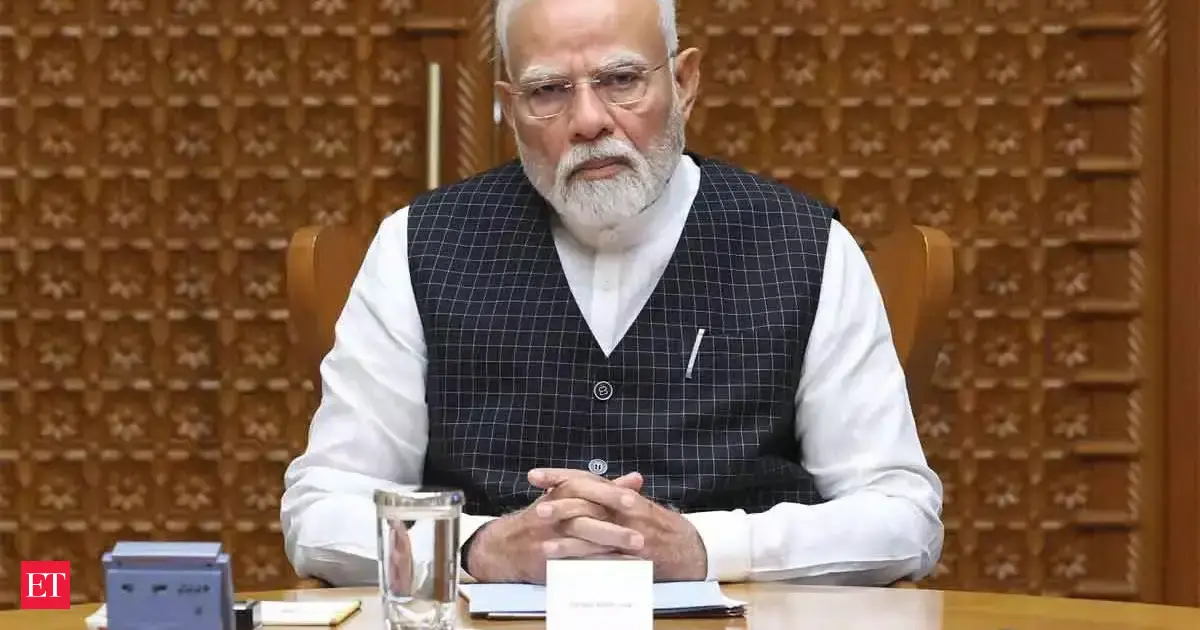

India's semiconductor sector is experiencing a period of rapid growth and transformation, driven by strong government support, strategic investments, and international collaborations. Prime Minister Narendra Modi has emphasized the country's commitment to building a robust semiconductor ecosystem to power its digital future and drive global innovation.

The Union Cabinet, led by Prime Minister Modi, has recently approved four new semiconductor projects under the India Semiconductor Mission (ISM). These projects, with a combined investment of approximately Rs 4,600 crore, will establish semiconductor manufacturing units in Odisha, Punjab, and Andhra Pradesh. This move is expected to create 2,034 skilled jobs and stimulate the electronics manufacturing sector, leading to additional indirect employment opportunities. With these new approvals, the total number of ISM-approved projects has reached 10, with a cumulative investment of around Rs 1.60 lakh crore across six states.

The four newly approved projects are from SiCSem, Continental Device India Private Limited (CDIL), 3D Glass Solutions Inc., and Advanced System in Package (ASIP) Technologies. SiCSem, in collaboration with Clas-SiC Wafer Fab Ltd. from the UK, will establish India's first commercial Silicon Carbide (SiC) compound semiconductor fab in Bhubaneswar, Odisha. This facility will manufacture Silicon Carbide devices with an annual capacity of 60,000 wafers and 96 million packaging units. The products will have applications in missiles, defense equipment, electric vehicles, railways, and other sectors. 3D Glass Solutions Inc. will also set up a vertically integrated advanced packaging and embedded glass substrate unit in Bhubaneswar, catering to defense, high-performance computing, AI, automotive, and photonics industries. CDIL will expand its production at its Mohali plant in Punjab. ASIP Technologies, in partnership with APACT Co. Ltd, South Korea, will launch a semiconductor manufacturing unit in Andhra Pradesh.

India's semiconductor market was valued at approximately US$38 billion in 2023 and is projected to grow to US$45–50 billion by the end of 2025. Further expansion to US$100–110 billion is expected by 2030. The India Electronics and Semiconductor Association (IESA) estimates that the market will reach around $64 billion by 2026, growing at a CAGR of over 19% from $27 billion in 2021. This growth is driven by increasing demand for electronics, electric vehicles, IoT devices, and 5G technologies.

The government has committed over ₹76,000 crore (~$10 billion) under the Semicon India Program, providing incentives for semiconductor fabs, display fabs, and design-linked incentives (DLI). Key investments include Micron Technology's $2.75 billion ATMP facility in Gujarat and Tata Electronics' proposed $11 billion investment to set up a chip fabrication unit in Dholera.

To support the growing chip design capabilities in the country, the government has provided design infrastructure to 278 academic institutions and 72 start-ups. In July 2025, the Ministry of Electronics and Information Technology (MeitY) approved 23 chip design projects from startups, MSMEs, and academic institutions.

India's first indigenous semiconductor chip is expected to be unveiled between September and October 2025. Initial production will focus on 28nm to 90nm technology nodes, used in automotive systems, telecommunications equipment, power management circuits, and industrial applications. The government has also initiated a program to train 85,000 engineers in advanced semiconductor and electronics manufacturing.

These initiatives demonstrate India's ambition to become a global semiconductor hub, fostering innovation, creating jobs, and contributing to the global supply chain.